PRODUCT DESIGN, Mechanical engineering

Overview

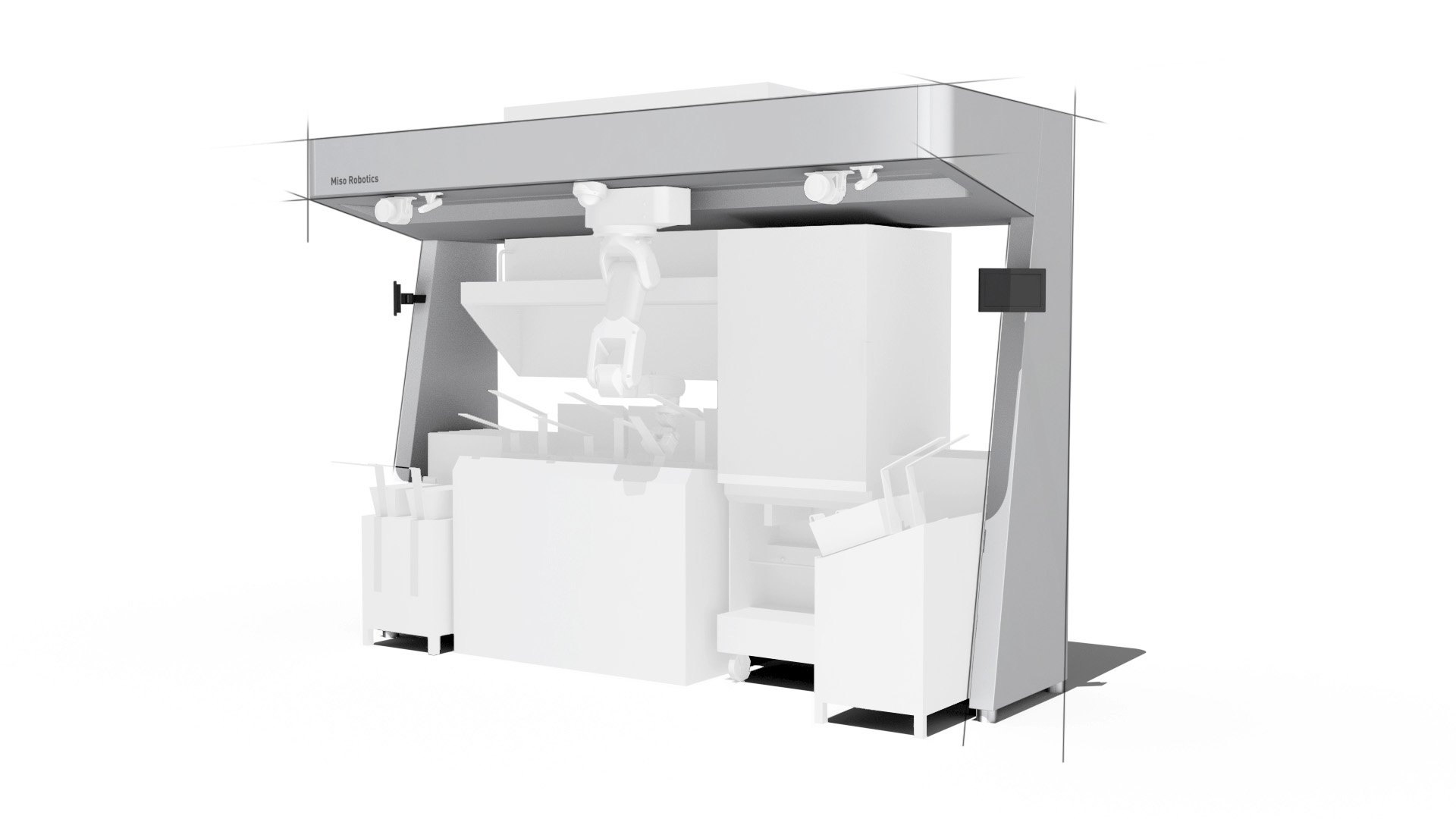

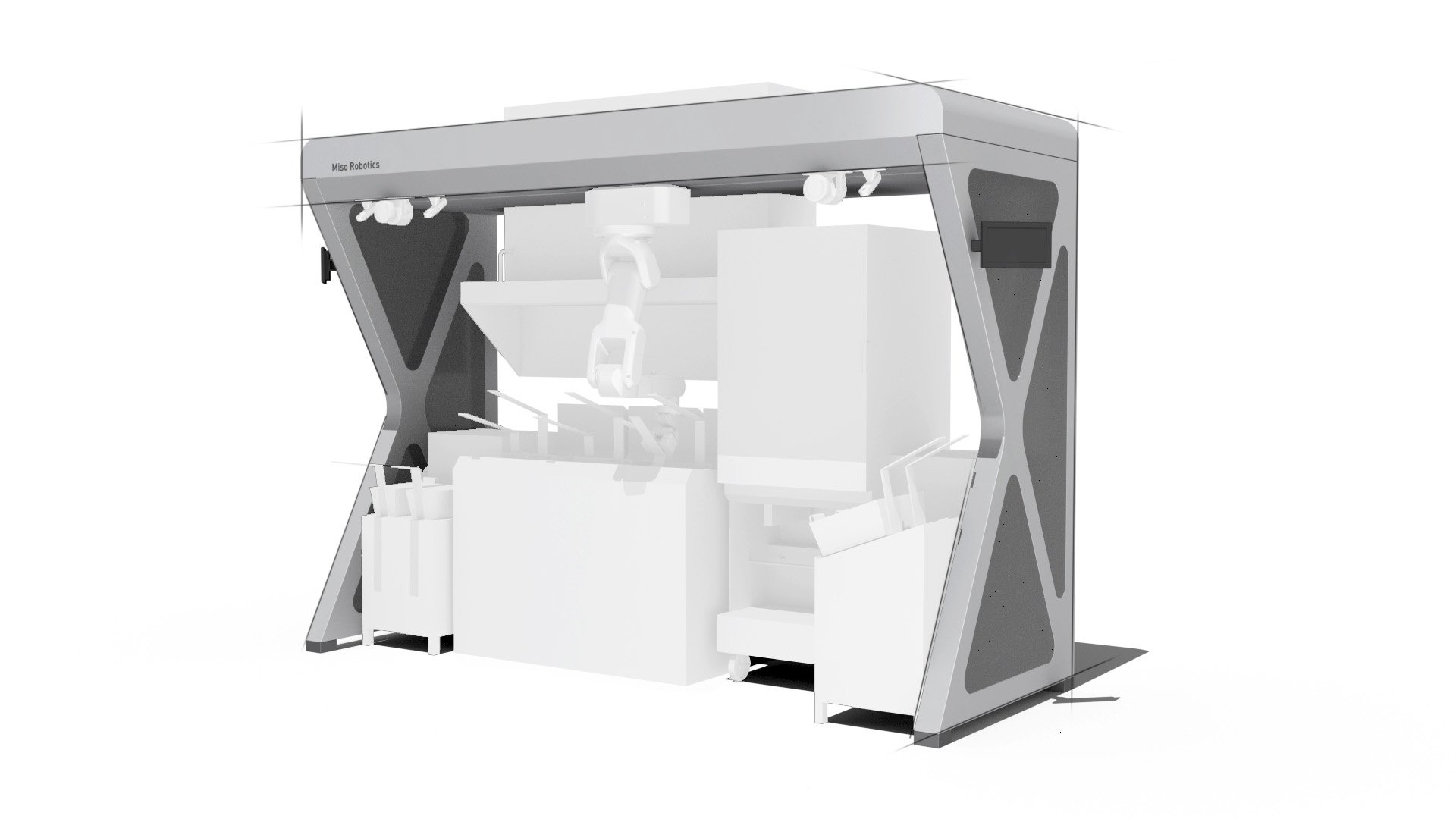

‘Flippy’ the food prep robot

_

Flippy is an innovative and advanced robotic system powered by Miso AI and designed to revolutionize the way cooking and food preparation are handled in commercial kitchens. It combines cutting-edge technology with culinary expertise to help chefs and restaurant staff streamline their operations and deliver consistent, high-quality food.

Equipped with an array of sensors, cameras, and intelligent algorithms that allow it to fry food, Flippy manages cooking times with precision. Its capabilities are not limited to a single type of cuisine or dish; Flippy can adapt to various cooking techniques and recipes, making it a versatile addition to any commercial kitchen environment. With collaborative automation, Flippy works alongside human chefs and kitchen staff to take on repetitive, time-consuming, and dangerous tasks, freeing people to focus on more creative and complex aspects of food preparation.

Because kitchen needs vary across the restaurant industry, Miso Robotics can customize Flippy in a variety of ways accommodating for kitchen size, food type, cooking volume and more. MINIMAL designers and engineers collaborated with Miso robotics to help create a pilot build suited to the kitchen needs of White Castle.

In the time since MINIMAL’s collaboration with Miso they have won awards like Fast Company’s Most Innovative Company, grown to serve clients like Jack in the Box and White Castle, and secured funding from investors like Ecolab.

Design challenges

Kitchen Complexities

_

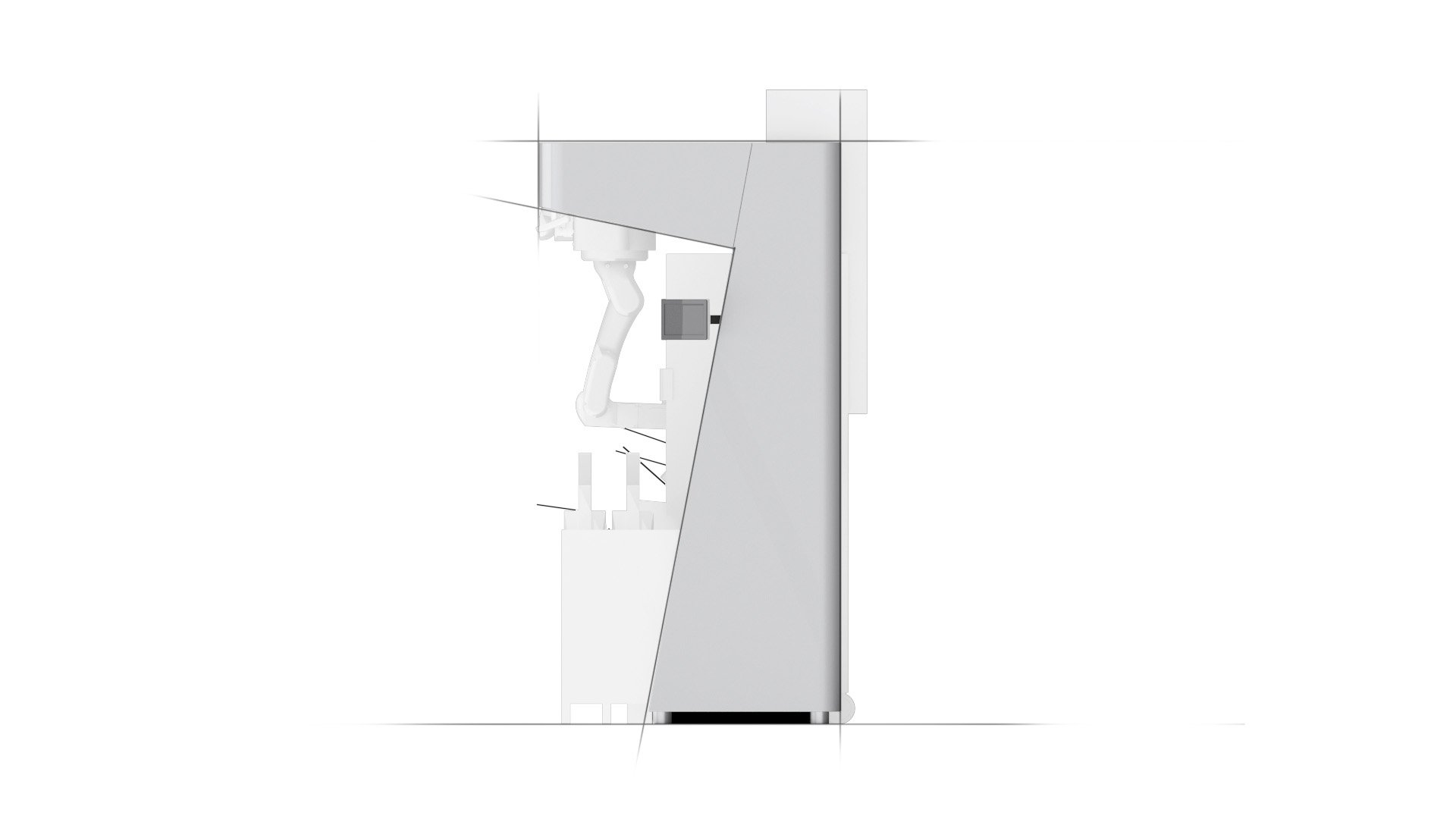

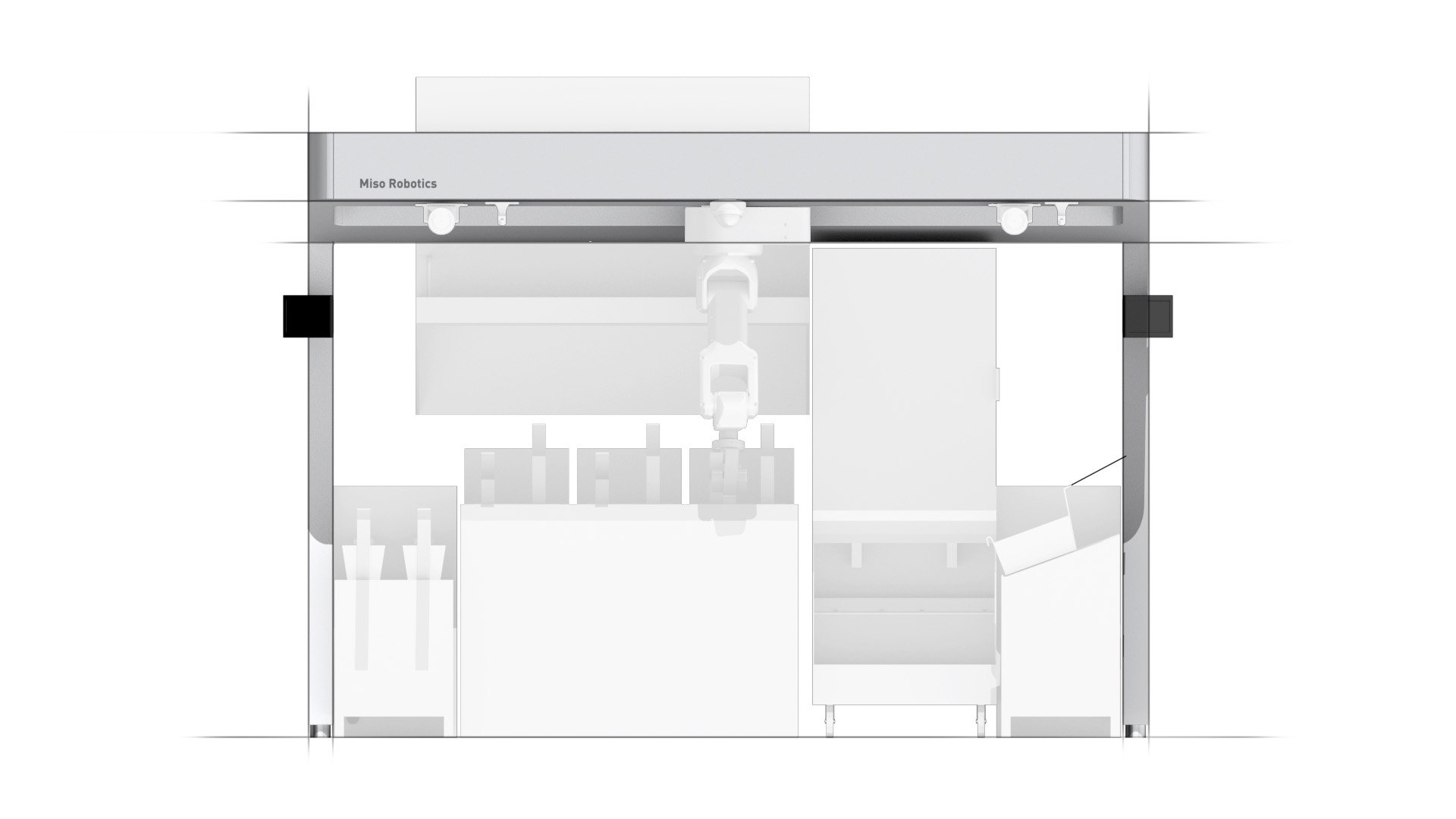

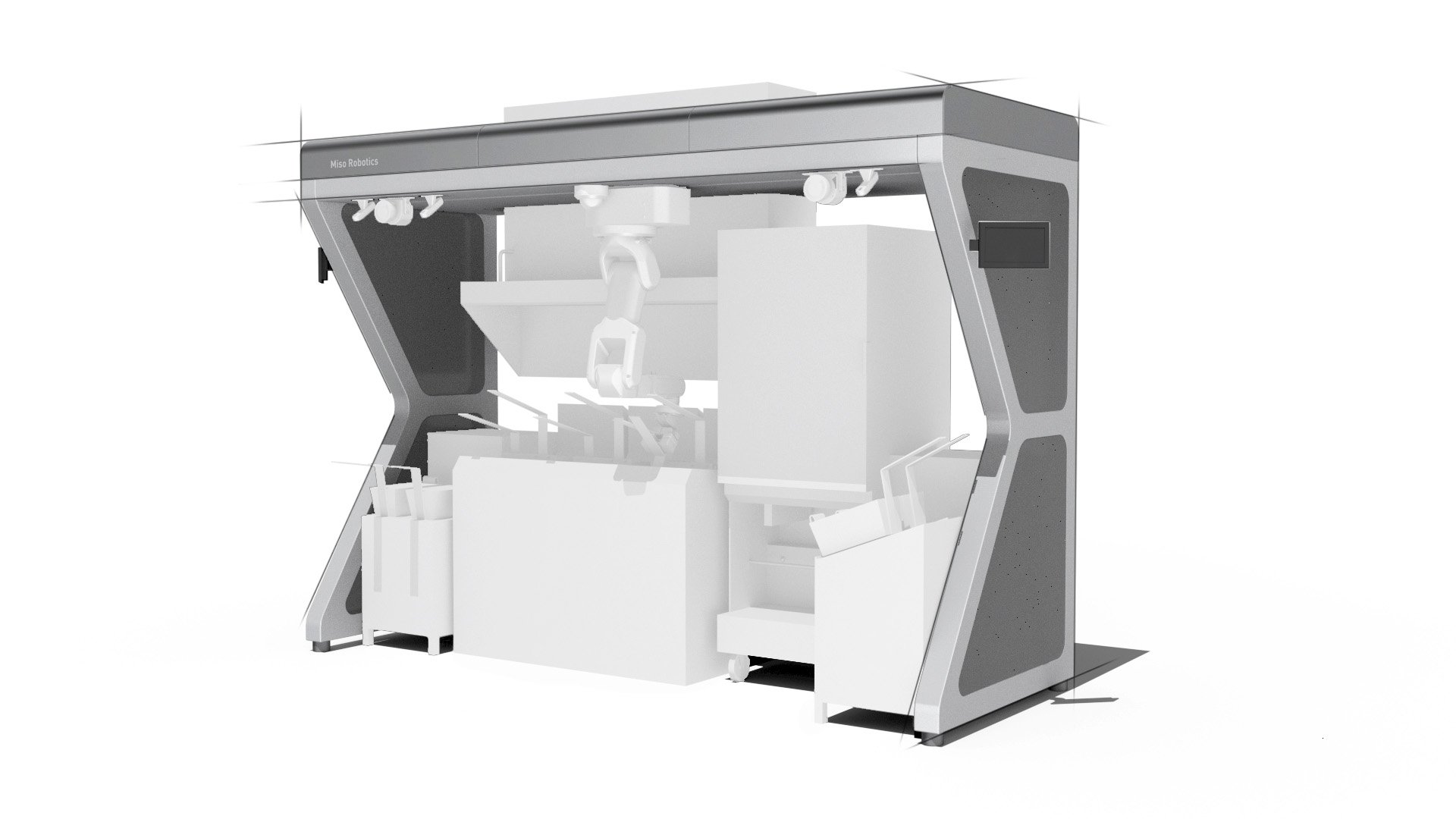

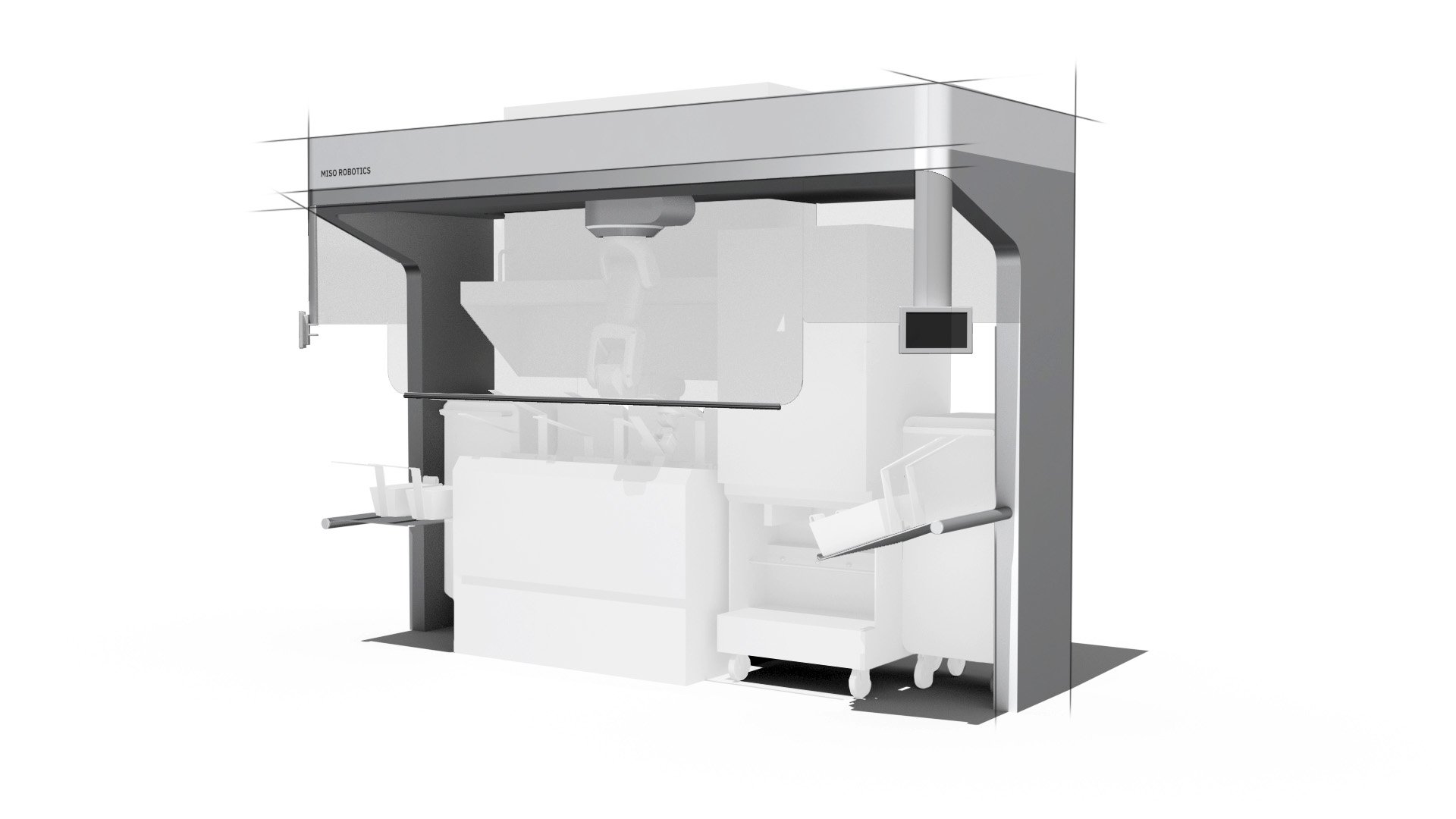

Commercial kitchens are highly regulated, complex spaces, and designing a kitchen robot, something with very little precedent, is no easy feat. MINIMAL designers and engineers had to consider safety regulations, cleanability, serviceability, space constraints and more while working with Miso Robotics on this build of flippy.

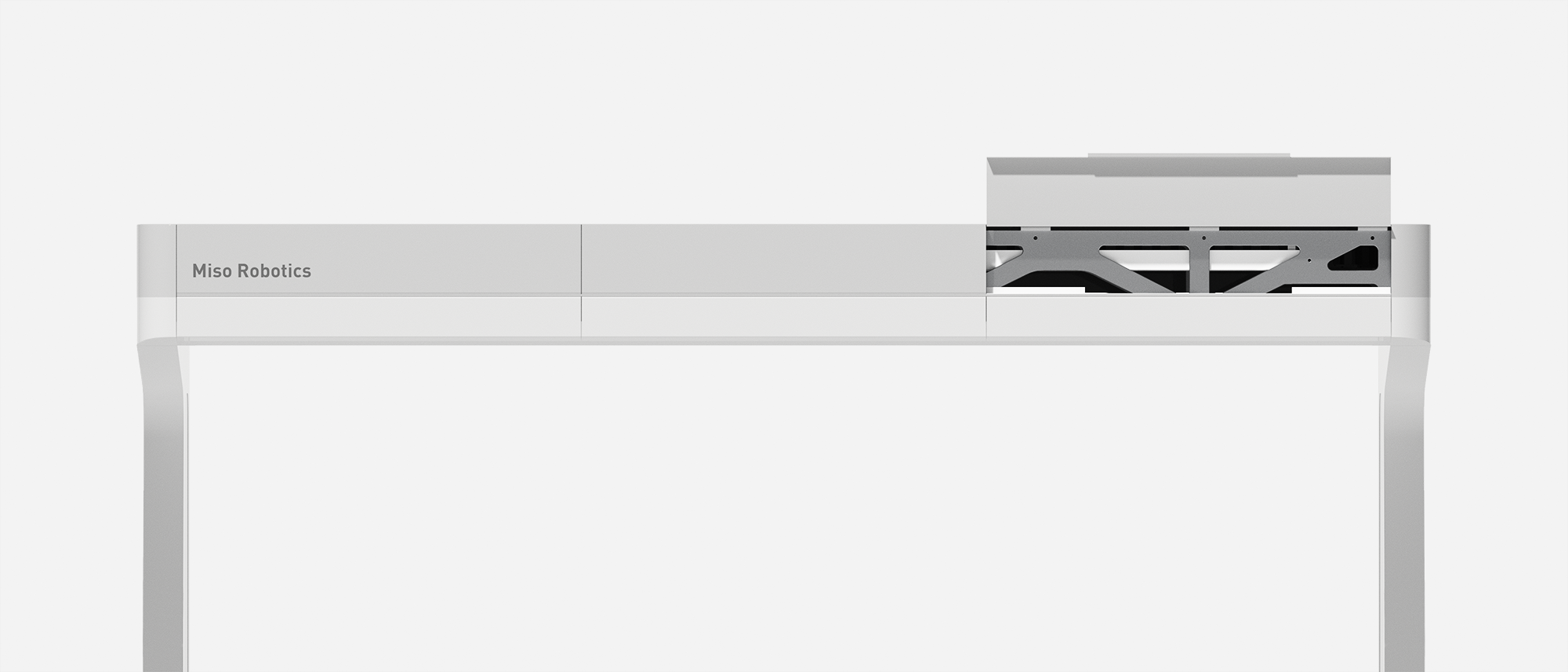

Flippy was designed out of sheet metal to be cost effective, durable and suited to kitchen safety standards: multiple panels cover the top chassis of Flippy to protect the internal components from grease while keeping them easily serviceable, the cantilever design gives Flippy structural stability while taking up as small a footprint as possible, and the open area around the legs gives workers access to easily clean the floor around Flippy.

Plexiglass doors can be assembled in front or be removed for safety and splatter purposes and the design includes plenty of negative space to make sure visual sign-lines in the kitchen remain as open as possible.

Overall MINIMAL’s collaboration has helped to secure White Castle as a lasting client of Miso Robotics and their partnership has continued to expand over the last couple of years.

Engineering

BUILT TO LAST

_

Flippy's exceptional adaptability and the strict regulations governing kitchen safety demanded a meticulous approach to its fabrication. To meet these challenges, our engineering team at MINIMAL played a pivotal role in creating strategic build architectures for the robot's structural framework. Recognizing the imperative for durability and hygiene, each Flippy unit is custom fabricated from high-grade stainless steel making certain design decisions challenging. Their expertise was instrumental in translating the design vision into reality while ensuring adherence to structural stability. The result is a seamlessly integrated, robust structure that not only upholds the aesthetic intent of Flippy but also underscores its reliability and safety in a dynamic culinary setting.