PRODUCT DESIGN, Engineering, Manufacturing liaison

overview

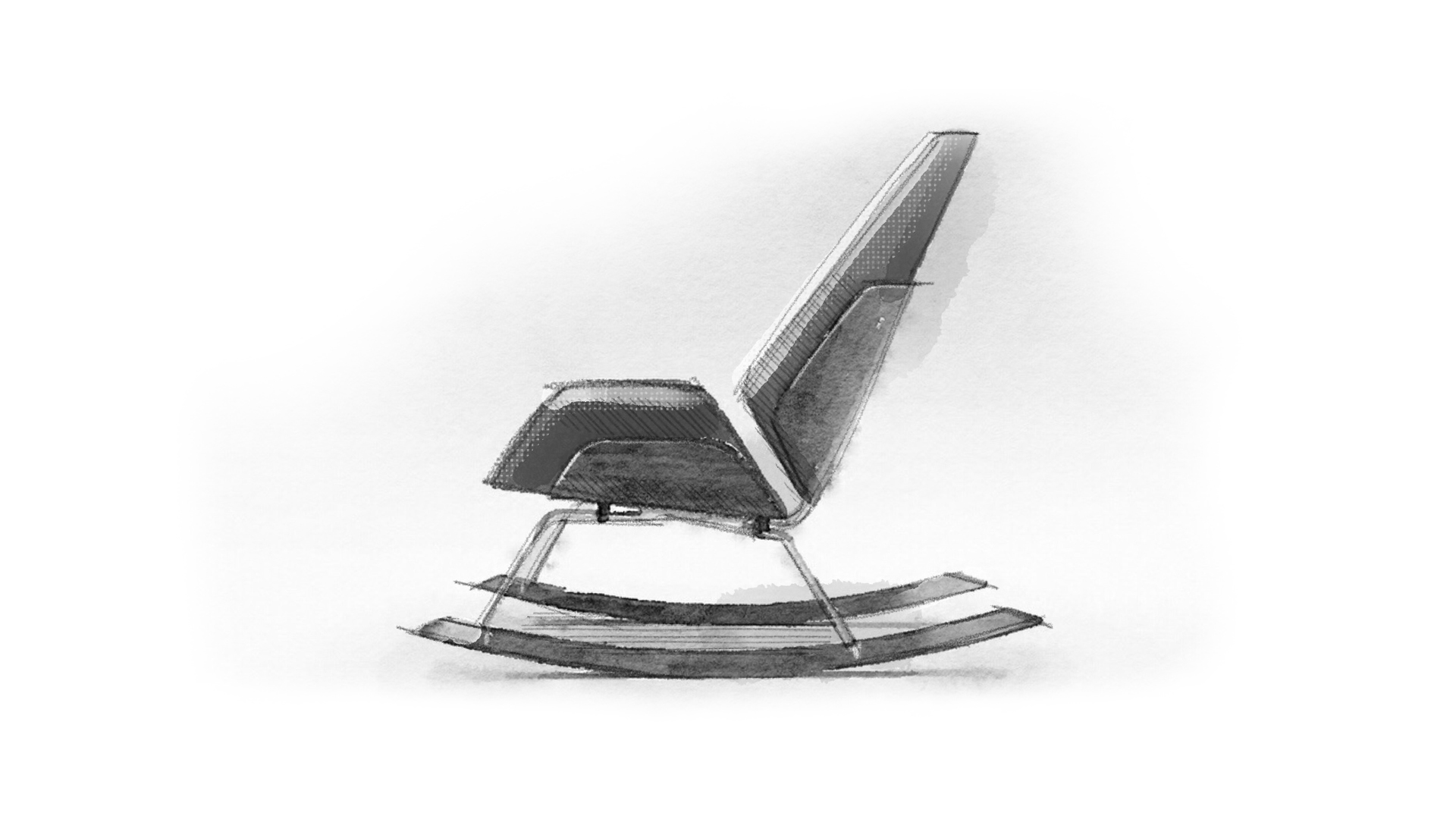

A modern, refined INTERPretation

_

The Fulton Rocker is a modern, refined interpretation of the classic rocking chair intended for both the residential market as well as the growing corporate segment focused on wellness and a more nurturing work environment.

We have known how to rock since our earliest memories. The classic rocking chair that our generation, and generations before us have grown up with, have a magical calming effect that slows life and helps one relax while inducing an almost trance like state of mind. Whether in the office or in the nursery, the rocking sensation provides many user benefits. The rocking motion releases endorphins which can improve mood and reduce stress and pain. Using a rocking chair increases blood flow around the body, thus sending more oxygen to the joints, which can help ease the symptoms of arthritis. Rocking chairs have said to help promote parent-child bonding, and there is even research to suggest that rocking a child can enhance emotional, social, cognitive and motor development.

As more and more companies invest in wellness for their employees to help offset the over-programmed and distracting world we exist in today, a rocking chair or lounge has unique benefit for employees. The Fulton Rocker is a personal and supportive oasis for users. It’s generous proportions and supportive sides allow users to freely adjust their posture and position. Our goal was to create a rocking lounge that better supported user’s needs as well as promoted more frequent and prolonged use by providing long-term comfort.

Whether users are escaping the chaos of the workplace, or bonding with their child in the wee hours of the night, the designer wanted to take the visceral connection that generations have had with the iconic porch high back rocker and create a new modern interpretation that will continue to create fond memories and emotional connections with the experience.

Modern Classic

Balancing aesthetics

and ergonomics

_

MINIMAL created a rocking lounge that balanced aesthetics, ergonomics and contract furniture durability requirements. Aesthetically our goal was to create an instant modern classic that mixed premium materials and allowed for easy customization between the layers of shells, upholstery, cushions and hardware. Ergonomically, the the Fulton Rocker provides generous support in multiple posture. The cupped sides help cradle the infant, and adult and help eliminate the inevitable head-snapping that occurs in all other rockers. The Fulton Rocker meets BIFMA standards without disrupting and diluting the sensitive proportions of the aesthetic elements.

Scott Wilson sketched the original concept for this chair as something that could transition from the nursery to the living room shortly after the birth of his first daughter.

Process

designing for parents and infants

_

During the design and development process, Scott Wilson observed many new parents with their newborns and infants as well as retailers in regards to rockers and gliders currently in market. This demographic had the most extreme needs and expectations when it came to the category. The belief was that if we could successfully design to meet the needs of these users then it would support other rocker customers. The hope was also that the rocker would also transition to the general living area from the nursery over time vs current solutions that typically

are discarded.

Every solution on the market was missing the mark on aesthetics or ergonomics. Only a few designs provided a timeless and refined aesthetic and even those failed on the ergonomics and comfort needed to support lounging and relaxing as well as cradling and comforting a child for long periods of time. After validating the initial insight, Scott Wilson created concepts that addressed ergonomic short-comings combined with a timeless modern design formula while balancing affordable domestic manufacturing techniques.

Multiple full-size foam “sit models” where made to dial in the comfort and sit angles before investing in induction plywood forming tools. In order to save on tooling dollars, the design was based around one plywood press tool that is mirrored about the seat pan and seat back division. Each side is then trimmed via CNC to produce the halves of the chair. The back is longer and the “arms” are trimmed off while the seat pan is shorter and the extended flaring in the tool creates the arms. The construction of multiple layers of wet and dry layers of wood allow all layers of the chair halves to be pressed at once including the outer cosmetic veneered layer. The inner layers are then upholstered. The multiple layered design allows for endless combinations of customer upholstery and wood veneers complementing any interior.